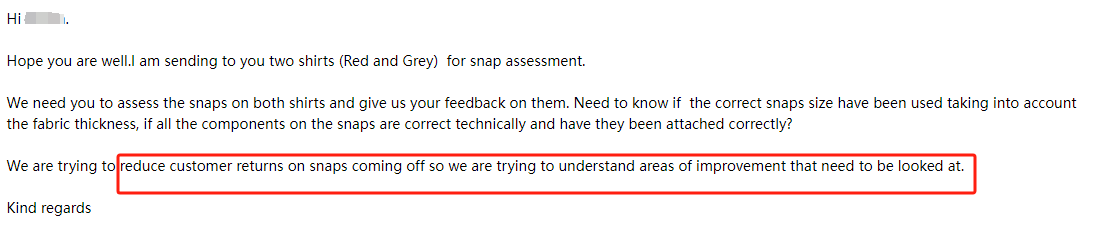

Be inspired by the customers we work with and help them minimize return issues.

1. The material of the buttons

The purity, tolerance, toughness and density of copper or zinc alloy, and whether it is environmentally friendly, will affect the final quality of the metal buttons and the degree of matching with the fabric.

2. The structure of the buttons

In the processing of buttons, the reasonableness, safety and stability of the structure of the buttons are standardized or not, which is directly related to the final performance of plastic buttons or metal buttons.

3. Installation of button mold production problems

Whether the workers accurately follow the thickness of the clothing fabric provided by the customer and the position of the four-in-one buttons placed to carry out the process of making the molds; after the button molds are made, whether the molds are tested in accordance with the test process to test whether the molds have reached the standard of shipment.

4. Whether the process of installing buttons is complete.

Installation of the button machine needs to be completed according to the guidelines, do not forget to lock the screws on the button machine. Some manufacturers do not have screws, and directly use adhesive paper to fix the buttons on the mold, which will also lead to the buttons fall off.

5. The size of the button accessories

Whether the length of the button pin matches the thickness of the clothing fabric, whether the thickness of the button is suitable for the clothing fabric, you need to consider these issues when choosing buttons.

We have been committed to providing customers with superior quality buttons, including metal buttons, plastic buttons, I-buttons, etc. We are also willing to provide professional answers for those who have questions, welcome to take your products to us to find the right buttons.

Please click the detail page to discover the buttons we made.

https://www.jt-tex.com/products-buttons.html