Shell buttons are widely used in many fields due to their unique natural beauty and diverse designs. The following are some of the main application areas of shell buttons:

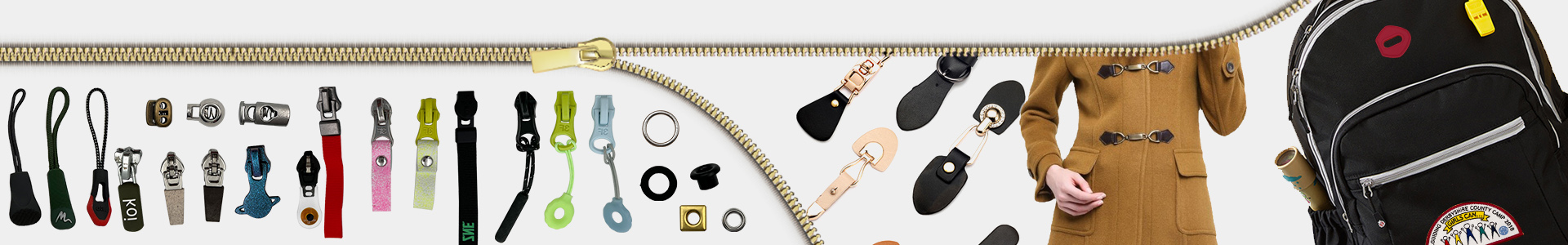

1. Garment industry:

- High-end suits, coats, shirts: shell buttons add nobility and elegance to these garments.

- Women's fashion: for dresses, tops, skirts, etc., adding a sense of fashion and uniqueness.

- Children's fashion: provide cute and natural decorative elements for children's clothing.

2. Bags and accessories:

- Handbags, backpacks, wallets: shell buttons are used as decorative or functional fasteners to enhance the products.

- Belt buckles: used to decorate belts and match with clothing to show personal style.

3. Shoes and hats industry:

- Footwear: such as decorative buckles on high-heeled shoes, casual shoes, boots, to increase the design of shoes.

- Hats: for fixing or decorating hats, adding fashion elements.

4. home decoration:

- Curtain buckles: as decorative and fixing elements for curtains.

- Furniture decoration: such as sofa, cushion, etc. above the decorative buckle.

5. jewelry:

- Shell buttons can be combined with metal and gemstones to make necklaces, bracelets, earrings and other jewelry.

6. crafts:

- Shell buttons are used to make all kinds of handicrafts, such as photo frames, decorative paintings, hanging ornaments and so on.

7. gift industry:

- Customized shell buttons are used for gift packaging to increase the uniqueness and commemorative value of gifts.

8. Ethnic specialty products:

- Shell buttons are widely used as traditional elements in some local characteristics or ethnic style clothing and accessories.

9. Stage costumes:

- Used in the decoration of stage performers' costumes to enhance the visual effect.

Let's find how to get more varieties of shell buttons.

Shell buttons are processed in a variety of processes, and different processes can produce buttons of different styles and effects. The following are some common processing techniques for shell buttons:

1. Cutting process:

- Slicing: cut the shells into thin slices and then polish them to the desired shape and size.

- Round Slicing: Shell is cut into round shape, suitable for making round buttons.

2. Sanding process:

- Polishing: The surface of the shell is polished with a polishing machine to give it a smooth finish and a natural luster.

- Sanding: The surface of the shell is sanded to produce a matte finish.

3. carving process:

- Shallow carving: Carve a shallow relief pattern on the surface of the shell.

- Deep carving: deeper carving on the shell to form a three-dimensional pattern.

4. Drilling process:

- Manual drilling: using a drill bit to manually drill holes in the shell for fixing buttons.

- Mechanical drilling: use mechanical equipment for batch drilling, more efficient.

5. coloring process:

- Coloring: Apply color to the surface of the shell, it can be a single color or multiple colors.

- Gradient Dyeing: Make the color of shell buttons gradually transition from the center to the outside, forming a gradient effect.

6. **Patchwork process**:

- Paste gold: paste gold foil or gold powder on the shell buttons to increase the luxury feeling.

- Paste diamond: Set small diamonds or gemstones on the shell buttons to enhance the grade of the buttons.

7. Combination craft:

- Combination of shells and other materials: combine shells with other materials such as metal, plastic, wood, etc. to create unique visual effects.

8. spray painting process:

- Spray painting: spraying paint on the surface of shell buttons, it can be glossy paint or matte paint.

9. Laser engraving process:

- Laser engraving: Using laser technology to engrave fine patterns or words on the surface of the shell.

Each process has its unique characteristics and scope of application, and designers can choose the appropriate process to make shell buttons according to the needs of the product.