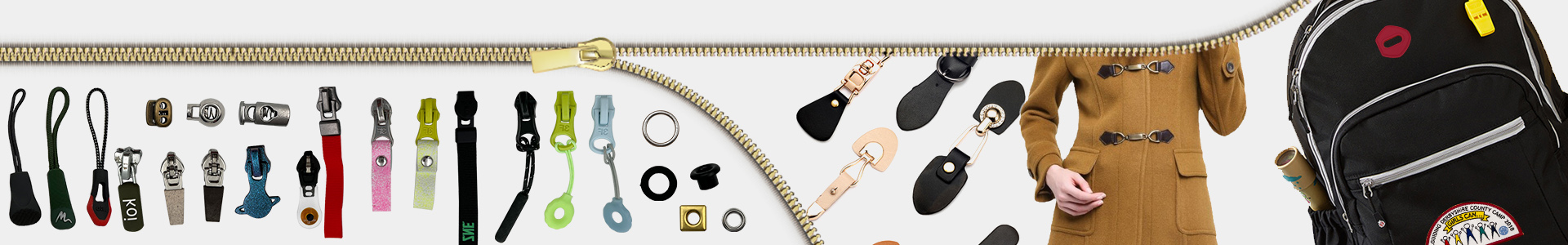

Waterproof zipper and traditional zipper have essential differences, ordinary fabric base are used textile fiber support, while the base of the waterproof zipper are used gel fiber material, and in the zipper teeth and chain head material is also very different, ordinary zipper is basically a plastic or metal parts, while the waterproof zipper more use of ultra-fine water-blocking materials, for the water blocking play a key role. Waterproof zippers not only block water but also block wind, so they are used more in down jacket and winter wears.

Now a lot of winter clothing, have reduced the sewing treatment, the use of paste waterproof process, especially the zipper bonding treatment, but also can not see the sewing of the needle and thread, paste PVC film waterproof zipper using the main material is PVC, the main ingredient for the polyvinyl chloride. tpu film is made of tpu granules, through a special process of making the film.

Coated waterproof zipper is characterized by no shedding, no whitening, no brittleness, and good waterproofing, which is widely used in cold-weather clothing, skiing clothing, down clothing, marine clothing, diving suit, tent, car and boat cover, raincoat, motorcycle raincoat, waterproof shoes, firefighting clothing, luggage, punching suit, fishing clothing and other waterproof related series of products.

The main factors to consider when choosing waterproof zippers are: the aesthetics of the product and the practical effect of waterproof. Waterproof zipper should be considered from the following aspects:.

waterproof zipper film does not tear.

the degree of smoothness, it is generally believed that the better the smoothness of the zipper, the better the quality of the waterproof zipper.

the surface of the waterproof zipper film is smooth and delicate, with a smooth feeling similar to leather, which is the appearance of high-quality waterproof zipper performance.

waterproof effect: the size of the center seam is directly related to the waterproof effect of the waterproof zipper, too large is obviously not waterproof, losing the significance of the waterproof zipper itself.

colored waterproof zipper color difference should be small, zipper tape color and fabric difference is the color difference, film surface color and tape surface color, color difference control within 5%.

service life, waterproof zipper on the laminated film quality is directly related to the service life of the waterproof zipper.

In the actual production or after-sales use should pay attention to

ironing: ironing is likely to cause the waterproof membrane off, if you have to iron, please operate at a temperature of less than 100 ℃ with a thin cloth;

Washing: in order to avoid damage to the waterproof membrane, do not use hot water, must be the waterproof zipper after washing. When drying, please dry naturally;

Dry cleaning: the dry cleaning conditions for waterproof zippers are likely to be different from those for clothing fabrics, so please check whether it can be dry cleaned beforehand;

Color diffusion (pollution): waterproof zipper is prone to chemical reaction with PVC, TPU membrane surface, it is likely to pollute the clothing fabric, please use the isolation cloth between the fabric and the waterproof zipper after sewing;.

Packaging of finished clothes: In order to prevent the color on the zipper from spreading to the fabric inside the clothes during transportation, please use thin paper for packaging between clothes and clothes and inside the clothes.