1. Material and Features

As Hypalon itself has good following Features:

Chemical resistance: good resistance to strong acids;

Weather resistance: able to resist the effects of climate and environment;

Ozone resistance: good resistance to ozone;

Oil, flame and abrasion resistance: good performance in oily environments, not easy to burn and abrasion resistance;

Electrical insulation resistance: good electrical insulation properties;

As well as heat resistance (145 ℃), low temperature resistance (-40 ℃), tear strength, excellent calendering.

The earliest used in automotive hoses, hoses, seals, wires and cables, anticorrosive coatings, waterproofing rolls, special tapes, adhesives and other specialty rubber products. Among them, Hypalon rubber compounded by calendering the film made of Hypalon compounded on the high-strength nylon cloth obtained Hypalon tape, long-term as a hovercraft kayak submarine wrapping materials used (1100D Hypalon)

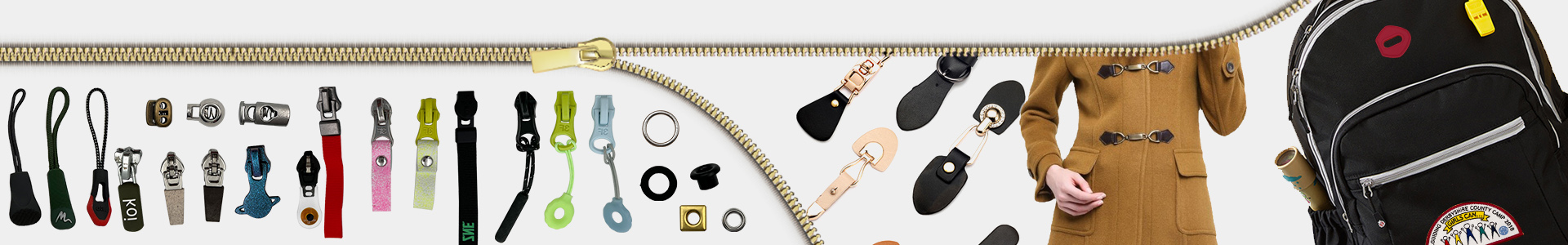

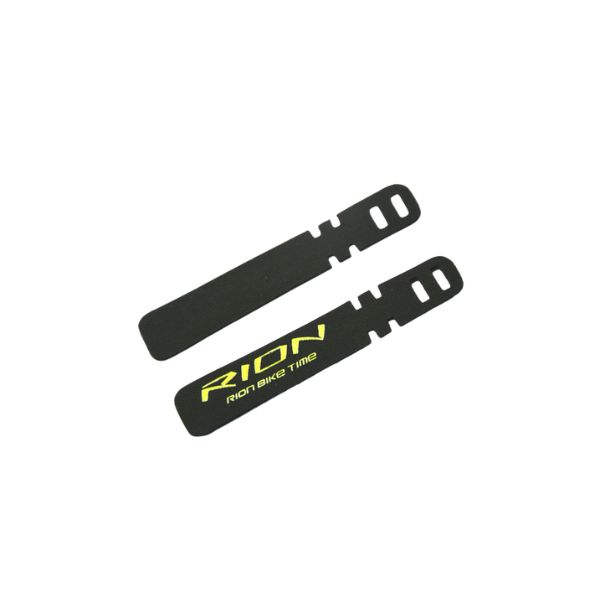

Hypalon was first used as the abrasion-resistant fabric for military tactical backpacks and tactical undershirts, and the use of Hypalon can also be seen in products such as Sog and Magforce in the current market. In terms of accessories, Hypalon slices are printed on Hypalon pull tabs, hitch tabs, sleeve tabs, cuff tabs and labels, which are often found on outdoor brand products.

2. Applications

Automotive industry: for automotive parts and coatings;

Hose, tape and rubber shoe industry: suitable for manufacturing industrial rubber products due to its chemical resistance and abrasion resistance;

Rubber boats and inflatable boats: suitable for water transportation due to its weather and chemical resistance;

Tents and waterproofing: for outdoor sports equipment and construction, etc;

Meanwhile, the application of Hypalon in apparel design mainly utilizes its unique physical and chemical properties, especially on apparel that requires abrasion resistance, chemical resistance and wear resistance, including:

Outdoor clothing and equipment;

Laboratory workwear;

Oiler's pants;

Rainwear, wetsuits, and waterproof shoes;

As knees, elbows and pockets of garments, utilizing Hypalon accessories for added durability;

As decorative elements of garments, such as badges, labels, zippers, pull tabs, etc., while providing functionality such as waterproofing and abrasion resistance;

High-tech sportswear, such as cycling, biking and skiing suits, which offer special protection to the user;

Military and tactical equipment, backpacks, jackets and gear, etc.

In the actual production process, we need to pay attention to the handling and sewing techniques of Hypalon materials and Hypalon accessories to ensure the overall quality of the garments. If you have any questions, please feel free to contact us, we are happy to provide you with answers.