What is Offset Stamping?

Belongs to a kind of thermal transfer printing, through the four-color overprint and become in the release paper or PET release film printed on the gel transfer special ink fabric stamping process, through the pattern of the reverse side of the hot melt adhesive to the image with a high pressure, the temperature of more than 100 degrees can be stamped on the fabric, followed by tearing away from the transfer paper or film. This way down, the image you want to stay on the fabric piece, and the effect is realistic, full degree of reproduction.

1.1 The advantages of the offset printing hot stamping?

Patterns are clear and realistic, the color effect can reach the photo effect (characters, landscape drawings,

etc.), the color is resistant to washing, stretching resistance mass production price is low

1.2 Suitable for type?

Batch customization, no requirement for breathable fabrics.

1.3 How about the effect?

The water does not fade, pulling will not crack.

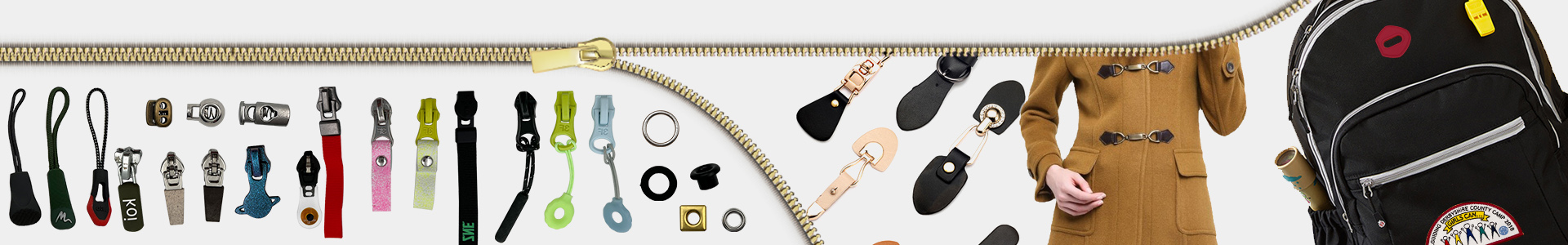

3D Offset Stamping Printing label

Silicone used in the garment industry and a new process - Silicone heat transfer, can be directly single-color or multi-color silicone flower pattern, silicone trademarks, logos, etc. with the hot stamping machine printed on clothing, gloves, shoes, hats, bags and other products, thickness 0.2-1.0mm. 3D Offset Stamping Printing label, after the transfer of environmental protection and non-toxic products, high elasticity, anti-pull anti-slip, waterproof, washable, stain-resistant wear-resistant, resistant to high and low temperatures, is not easy to age, and can be keep the color bright for a long time (not fade).

Toys, shoes, clothing, beauty boxes, bags, etc., you can utilize offset printing labels to make them unique. If you are worried that the traditional inkjet printing or UV printing colors are not long lasting enough or the graphics are not too clear, then try 3D offset heat transfer labels, using non-toxic and environmentally friendly silicone to make your products more popular and reduce after-sale complaints.

Because of its heat transfer process is easier to use compared with other direct screen printing, just put the transfer paper pattern on the surface of the transferred object such as fabric (cloth piece), and then use the hot stamping machine or iron to press the iron for a number of seconds after the pattern will be transferred to the object, it is convenient and not easy to fall off. It can be used on garments, decorative fabrics and other kinds of fabrics. It's totally a environmentally friendly product.

Use below informations for a better quotation,

(1) need to silicone heat transfer product files or actual samples

In order to make a product that meets the effect you want, the first thing that is necessary is the style of

the product. The drawing of the product is an important way to describe the product, part of the format

of the drawing or even directly get the size of the product, such as AI documents; if the pursuit of effect,

the actual sample is another option. Through the actual sample, can be more intuitive to show the effect

of the product needed.

(2) Need to silicone heat transfer product specifications size

The specification size is a necessary prerequisite for the quotation, because different specification size

will correspond to different processes, which will greatly affect the price of the high and low.

3)Effects of silicone heat transfer products

Surface effect: plane/curved surface; glossy/matt surface

Plane: as the name suggests, that is, the surface is flat; curved surface: that is, the surface has a curvature, the curved surface can be divided into arcs, triangular arcs and other arcs.

Glossy: as the name suggests, that is, the surface is more bright, shiny; matte: the surface is not reflective,

more natural.

4) Whether the product needs to be adhesive backing

Product backing, that is, the back of the product will be coated with a layer of special glue, used for hot

stamping. Jagos special adhesive backing is the use of imported environmentally friendly materials,

odorless and non-toxic.

If the product is not adhesive backed, it is mostly used for sewing stamps.

5) Need product hot stamping fabric

Due to the special nature of the silicone material, not for: leather, waterproof fabric, (because leather and

waterproof fabric has a layer of coating on the surface, heat transfer hot stamping Logo and coating

bonding, and the actual leather and fabric bonding is not, so the bonding fastness is not strong).

However, after the unremitting research of the technical department of Jagos, part of the leather and

waterproof fabrics can also use silicone hot stamping label, but need to be tested first.

Therefore, if you need to iron to leather, waterproof fabrics, you need to be tested by Gagos fabrics first,

to analyze the parameters of the hot stamping. Prevent the phenomenon of hot stamping is not firm.

Click link to know more about our High color saturation 3D Offset Stamping Printing label,

https://www.jt-tex.com/product-jt-tex-offset-label-engraving-film.html